Premium TAD Jumbo Rolls – Softness & Strength for High-End Converting

Trusted by converters worldwide, our TAD tissue delivers exceptional bulk, absorbency, and custom OEM support.

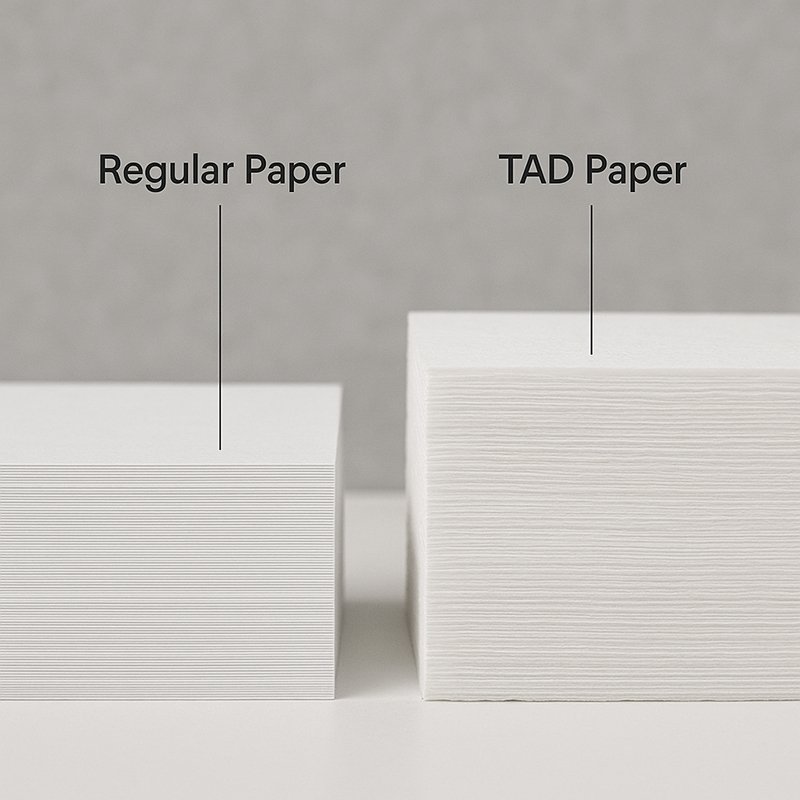

At Sansheng, we specialize in manufacturing high-quality TAD (Through-Air-Dried) tissue jumbo rolls, providing superior softness, strength, and bulk for premium converting applications.

Our TAD jumbo rolls are ideal for producing top-tier toilet paper, kitchen towels, and napkins for brands that demand the best.

Exported to over 30 countries, trusted by leading tissue converters worldwide.

Is your current tissue supply..

Tearing during converting?

Too thin or uneven in softness?

Causing customer complaints?

Then try working with us! Our products can

Resists tearing during converting and rewinding

Thicker and softer at the same basis weight

High quality with fewer customer complaints

TAD Tissue Jumbo Roll Specifications

Detailed specifications to help you make the right converting choice.

| ltem Name | Color | Ply | GSM | Roll Width | Roll Length | Roll Dia |

|---|---|---|---|---|---|---|

| TAD Jumbo Roll - Paper Towel | white | 1 | 21~30gsm | ≤2850mm,can be customized | can be customized | 1000mm~1200mm,can be customized |

| TAD Jumbo Roll - Kitchen Towel | white | 1 | 21~30gsm | ≤2850mm,can be customized | can be customized | 1000mm~1200mm,can be customized |

| TAD Jumbo Roll - Toilet Paper | white | 1-2 | 17~25gsm | ≤2850mm,can be customized | can be customized | 1000mm~1200mm,can be customized |

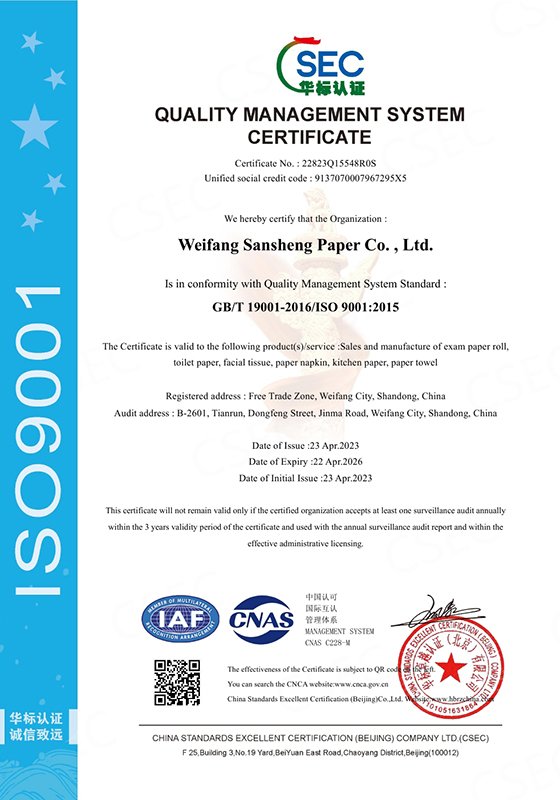

Certificates and Sales Network

Certificates obtained by Sansheng Paper Industry and network of cooperative customers

TAD Tissue Jumbo Roll Shipment

Secure Packaging, Reliable Loading, and On-Time Delivery to 30+ Countries Worldwide

40HQ container packing method

When less than 2.69 meters

When greater than 2.69 meters

40HQ Container loading and delivery site real photo

Applications of Sansheng TAD Jumbo Rolls

Versatile base paper for premium tissue, towel, and hygiene products.

Household Products

Premium toilet tissue & Soft and strong kitchen paper towels

Food Service & Hospitality

High-absorbency napkins & Luxury facial tissues

Industrial Converting

Base rolls for OEM and private label brands

Advanced Production Capability

Equipped with world-class TAD machines for consistent quality and high output.

Our factory is equipped with state-of-the-art TAD forming and drying systems, ensuring high-volume production with uniform sheet properties.

🔹 Monthly capacity: 3,000+ tons

🔹 Lead time: 20–30 days after order confirmation

🔹 OEM/ODM services: Full private label support, custom packaging available

What Our Customers Say

Real feedback from trusted partners in 30+ countries.

Transaction Reviews from TAD Jumbo Rolls

Mrs.Miller(Importer Form USA):

"Since switching to Sansheng's TAD jumbo rolls, our kitchen towel sales have increased significantly. The softness and absorbency have left a strong impression on our customers."

Transaction Reviews from TAD Parents Rolls

Mr.Taylor(Tissue Converter Form England):

“Reliable quality and stable supply. The customized basis weight fits perfectly for our converting machines.”

* 30+ countries served. 3,000 tons/month capacity. 100% OEM supported.

Need More Details? Get a Custom Quote Now.

Explore common TAD paper questions or send us your project details — we respond within 24 hours.

Frequently Asked Questions (FAQ)

Our standard lead time is 20–30 days after order confirmation. For repeat orders or urgent shipments, we offer expedited production slots.

Yes. We support customized basis weight, width, and roll diameter based on your converting equipment requirements.

Rolls are wrapped in PE film and kraft paper for moisture protection and palletized for safe transportation.

Yes, free A4-size sheet samples or small roll segments are available. Shipping costs may be covered by the buyer or deducted from your first order.

Currently, we use high-quality virgin wood pulp. FSC certification is under planning. Please let us know if this is a key requirement.

Yes. We support small-volume trial orders to help you test compatibility and quality before placing larger quantities.